Air Pollution Prevention

Nan Pao Group's air pollution control efforts primarily target toluene, xylene, total VOCs, non-methane hydrocarbons, and particulate pollutants. For exhaust gas management, pollutants are classified by their characteristics, collected through enclosed systems or hoods, and then treated using appropriate equipment such as bag filters, condensation recovery systems, etc., to ensure compliance with emissions standards. To further reduce pollutant emissions, the company actively optimizes production processes at the source and continues to introduce high-efficiency pollution control equipment.

Since 2020, Nan Pao Foshan has utilized a regenerative thermal oxidizer (RTO) forhigh-temperature decomposition and energy recovery to treat VOCs. In 2022, Nan Pao

Taiwan implemented a regenerative catalytic oxidizer (RCO), along with scrubbers and condensation systems, to enhance the collection and reduction of volatile organic

compounds. Through a combination of pollution prevention measures, the company is dedicated to minimizing the environmental impact of air pollutant emissions.

Greenhouse Gas Emission of Nan Pao Taiwan

TW Air Pollution.png)

In 2024, Nan Pao Taiwan recorded volatile organic compounds (VOCs) emissions of 62.971 metric tons, a reduction of 0.739 metric tons (-1.16%) compared with 2023. The VOC intensity was 0.0091, representing a 14.95% decrease year-on-year. This reduction was primarily attributable to the Company's adoption of the regulatory authority's recommendation in 2024 to exclude externally purchased raw materials from the calculation of input quantities, thereby lowering the estimated VOC emissions.

VOC Emission Intensity of Nan Pao Group

TW Air Pollution.png)

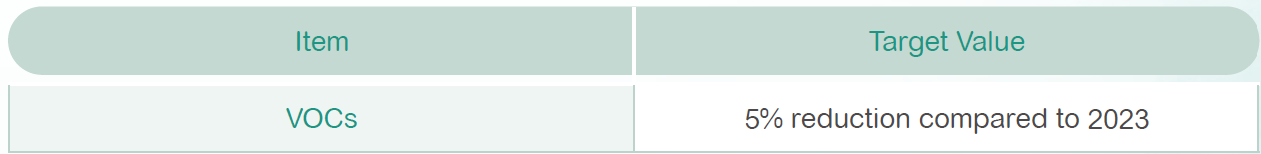

In 2024, Nan Pao Group recorded volatile organic compounds (VOCs) emissions of 68.183 metric tons, a reduction of 2.469 metric tons (-3.49%) compared with 2023.

The VOC emission intensity was 0.0040, representing a 14.89% decrease year-on-year, successfully achieving the annual target of a 5% reduction compared with 2023.

The decline in emissions was primarily due to the recalculation of VOC emissions at Nan Pao Resins Taiwan, as well as the installation of new exhaust gas treatment equipment at Vietnam Advanced Materials, which further improved treatment efficiency.

Considering variations in production volume and product pricing, the Group achieved significant improvements in 2024 but will continue to adopt a prudent advancement strategy in 2025. A new target has been set to reduce VOC emission intensity by 10% compared with 2023, with ongoing efforts to strengthen process management and pollution control to minimize environmental impact.